Student Projects

We offer interesting student projects for Semester, Bachelor and Master thesis.

You can find here some examples of student projects in our group.

Alternatively, you can check the subject areas descriptions further below to identify a particular interest and contact the appropriate person.

Has the content of our research caught your interest but there are no open projects? We are happy to receive your spontaneous application and have a chat with you.

Past are the days where mechanical testing of materials was limited to a force-elongation curve obtained with a simple uniaxial testing apparatus! Our lab is equipped with several modern testing set-ups which are continually extended and improved. By a combination with optical methods to track the deformation of the tested materials on a macroscale (a few mm), but also by means of microscopic techniques (a few µm), valuable information about the multi-scale characteristics of materials can be gained. This requires appropriate techniques and tools to be developed both in terms of testing components and protocols as well as computer programs for data processing, analysis, and visualization.

Interested in this topic? Contact

Further reading from our group:

Ehret A.E., Bircher K., Stracuzzi A., Marina V., Zündel M., Mazza E., 2017, Inverse poroelasticity as a fundamental mechanism in biomechanics and mechanobiology, Nature Communications, 8, 1002. DOI: 10.1038/s41467-017-00801-3

Pensalfini M., Haertel E., Hopf R., Wietecha M., Werner S., Mazza E., 2017, The mechanical fingerprint of murine excisional wounds, Acta Biomaterialia, 65, 226-236. DOI: 10.1016/j.actbio.2017.10.021

Bircher K., Ehret A.E., Mazza E., 2017, Microstructure based prediction of the deformation behavior of soft collagenous membranes, Soft Matter, 13, 5107-5116. DOI: 10.1039/C7SM00101K

Once one has collected enough experimental data that reveal the response of a material under well-defined testing conditions, it is often necessary to rationalize the observed behavior using appropriate model equations. This allows, for example, predicting the influence of changes in a material’s microstructure, and simulating its response to complex mechanical configurations. This is where non-linear continuum and structural mechanics come into play, which provide the physical laws and mathematical tools necessary to deal with these challenging problems. Classical concepts are combined with novel formulations to explain the mechanics of soft materials, such as soft elastomers, gels, non-wovens, textiles and, of course, soft biological tissues. Recent developments exploit the possibilities offered by a direct representation of the heterogeneous microstructure of materials in representative volume elements, including, for example, discrete fiber networks and multiphasic matrix materials.

Interested in this topic? Contact

Further reading from our group:

Stracuzzi A., Mazza E., Ehret A.E., 2018, Chemomechanical models for soft tissues based on the reconciliation of porous media and swelling polymer theories, Z Angew Math Mech, 1-20. DOI: 10.1002/zamm.201700344

Zündel M., Mazza E., Ehret A.E., 2017, A 2.5D approach to the mechanics of electrospun fibre mats, Soft Matter, 13, 6407-6421. DOI: 10.1039/C7SM01241A

Mauri A., Hopf R., Ehret A.E., Picu C.R., Mazza, E., 2016, A discrete model to represent the deformation behavior of human amnion, Journal of the Mechanical Behavior of Biomedical Materials, 58, 45-56. DOI: 10.1016/j.jmbbm.2015.11.009

Ehret, A.E., 2015, On a molecular statistical basis for Ogden's model of rubber elasticity, Journal of the Mechanics and Physics of Solids, 78, 249–268. DOI: 10.1016/j.jmps.2015.02.006

The interaction between cells and their mechanical environment has become an emerging research topic due to the influence of e.g. substrate topography and stiffness, or marco- vs. microscopic deformability on cell behavior, such as their proliferation, differentiation, migration, and orientation. Providing cells in tissue-engineered materials and biomedical devices with an appropriate mechanical environment is essential for their successful integration in clinical applications; examples are the development of endothelialized cardiovascular devices within the Zurich Heart project or tissue-engineered skin substitutes in the external pageSkintegritycall_made project. We work with traction force microscopy for assessing cellular forces exerted on soft materials. We design dedicated dynamic bioreactors that provide controllable mechanical stimuli to cells. These tools are used to advance our understanding of the coupling between cell biology and mechanics.

Interested in this topic? Contact

Further reading from our group:

Zündel M., Ehret A.E., Mazza E., 2017, Factors influencing the determination of cell traction forces, PLOS ONE, 12(2):e0172927 DOI: 10.1371/journal.pone.0172927

Bergert M., Lendenmann T., Zündel M., Ehret A.E., Panozzo D., Richner P., Kim D.K., Kress S.J.P., Norris D.J., Sorkine-Hornung O., Mazza E., Poulikakos D., Ferrari A., 2016, Confocal reference free traction force microscopy, Nature Communications, 7, 12814 DOI: 10.1038/ncomms12814

Bachmann B.J., Bernardi L., Loosli C., Marschewski J., Perrini M., Ehrbar M., Ermanni P., Poulikakos D., Ferrari A., Mazza E., 2016, A Novel Bioreactor System for the Assessment of Endothelialization on Deformable Surfaces, Scientific Reports, 6, 38861 DOI: :10.1038/srep38861

An improved understanding of the mechanical behavior of native tissues and biomedical materials and the ability to perform computer-based simulations and mechanical analysis represent valuable resources for the development of biomedical equipment for therapy or diagnosis. In close collaboration with medical doctors and biologists, we work on simulations to better understand the interaction of these devices with the human body, and devise improved solutions. Another aspect concerns transferring tissue characterization techniques from in-vitro to in-vivo applications, e.g. as diagnostic methods to detect changes related physiological or pathological processes in the human body.

Interested in this topic? Contact

Further reading from our group:

Müller B., Elrod J., Pensalfini M., Hopf R., Distler O., Schiestl C., Mazza E., 2018, A novel ultra-light suction device for mechanical characterization of skin, PLOS ONE, 13(8): e0201440. DOI: 10.1371/journal.pone.0201440

Hopf R., Gessat M., Russ Ch., Sündermann S.H., Falk V., Mazza E, 2017, Finite Element Stent Modeling for the Post-Operative Analysis of Transcatheter Aortic Valve Implantation , Journal of Medical Devices, 11(2). DOI: 10.1115/1.4036334

Maurer M.M., Badir S., Pensalfini M., Bajka M., Abitabile P., Zimmermann R., Mazza E., 2015, Challenging the in-vivo assessment of biomechanical properties of the uterine cervix: A critical analysis of ultrasound based quasi-static procedures, Journal of Biomechanics, 48, 1541-1548. DOI: 10.1016/j.jbiomech.2015.02.038

Metal Additive Manufacturing (MAM) opens completely new opportunities for the optimum design and manufacture of high-value components used in various industry sectors, including biomedical, aerospace, automotive, etc. As an example, it allows for the fabrication of lattice-based biomedical implants with improved mechanical biocompatibility and osseointegration. Mechanical characterisation and development of reliable mechanical integrity assessment solutions for these new materials are crucial to qualify them for employment in critical load-bearing applications. Our group at Empa aims to evaluate the long-term mechanical integrity of additively manufactured materials and structures, e.g. under fatigue or creep loading conditions. Importantly, advanced mechanical analysis methods, combining finite element method and machine learning, are being developed for the mechanical assessment of complex-geometry components.

Interested in this topic? Contact

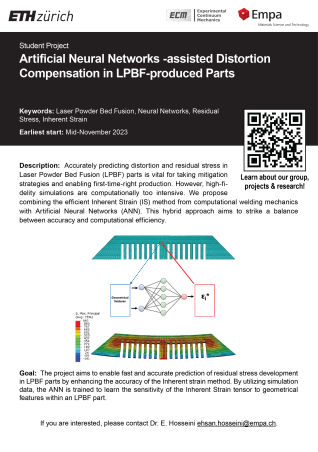

A thorough quantitative understanding of the Metal Additive Manufacturing (MAM) process requires insights from different types of computer simulations, namely: thermal, mechanical, metallurgical, and fluid-dynamics. The extremely high computational cost of such multi-physical fields simulations has been addressed in previous research by either decreasing the simulation domain size and/or by adopting gross simplifications. Our group at Empa aims to exploit the power of multiscale modelling and machine learning algorithms to moderate the computational cost of such simulations and realise reliable component-scale simulations for MAM.

The underlying idea originates from the incremental build nature of MAM and the fact that the involved phenomena during deposition of the material increments are very similar at each location. The variation in the characteristics of the deposited increments does not originate from a significant change in the involved physics but only from a (modest) change in the imposed boundary conditions. Component-scale simulations of MAM process can therefore be considered as solving a large number of nominally similar small-scale models, each under different boundary conditions than the rest. The computational cost of such repetitive simulations can thus be significantly reduced by employing machine learning toolboxes.

Interested in this topic? Contact

Towards Robust Probabilistic Structural Analysis: Uncertainty Propagation using Physics-Informed Neural Networks

This project aims to address the limitations of deterministic and traditional probabilistic methods in structural analysis by employing Physics-Informed Neural Networks (PINNs). Deterministic methods often overlook inherent uncertainties in material properties and load conditions, while traditional probabilistic methods like Monte Carlo + FEM simulations are computationally intensive. PINNs emerge as a promising tool for efficient uncertainty quantification. The project's primary objective is to assess the feasibility and challenges of using PINNs for propagating uncertainties from material parameters to solution quantities such as stress and strain.

Keywords

Physics-Informed Neural Networks (PINNs), Finite Element Analysis, Uncertainty Quantification, Structural Analysis

Labels

Master Thesis

PLEASE LOG IN TO SEE DESCRIPTION

More information

Open this project... call_made

Published since: 2024-02-12 , Earliest start: 2023-11-01 , Latest end: 2024-04-01

Applications limited to ETH Zurich

Organization Experimental Continuum Mechanics

Hosts Hosseini Ehsan

Topics Engineering and Technology